In process lines where space is limited, regulatory requirements are strict, and maintenance must be carried out safely, selecting the right isolation system is not something to leave to chance. DBB (Double Block & Bleed) monoflange valves are designed to meet this challenge: reducing volume without compromising performance, safety, or compliance.

In industrial systems where every millimetre matters, compact solutions are not a luxury—they’re a necessity. And when we talk about reliability, safety and efficiency in critical process lines, DBB monoflange valves become a smart technical and strategic choice.

In this article, we explain what they are, why their use is increasing in sectors like Oil & Gas, energy, chemical and water treatment, and how Sistemiza integrates these valves as a key component in its fluid control and handling systems.

What is a DBB monoflange valve?

A DBB valve allows you to isolate a section of piping with two independent shut-off mechanisms while venting the cavity between them. This setup is essential when safe maintenance is required or when residual pressure needs to be eliminated.

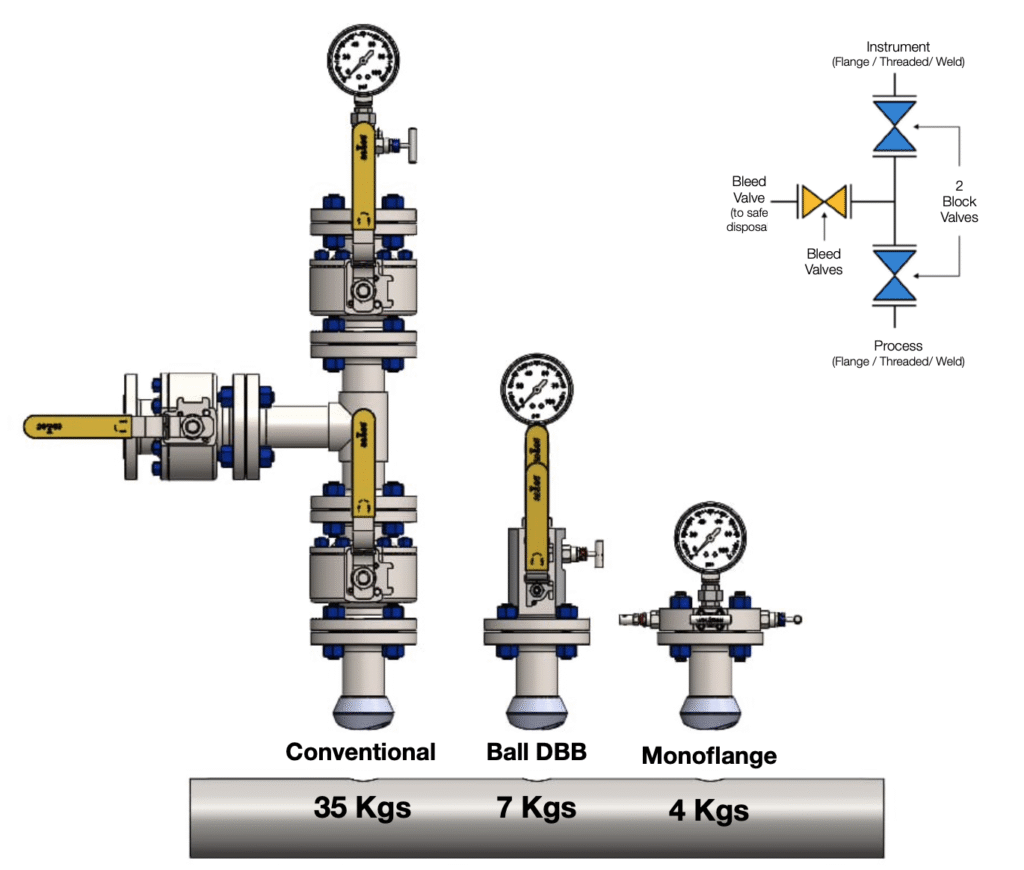

The monoflange version integrates this functionality into a single forged or machined body, eliminating the need for multiple separate valves and connections. The result:

- Fewer connections ⇒ Fewer leakage points

- Fewer parts ⇒ Lower assembly and maintenance costs

- Reduced footprint ⇒ Perfect solution for limited-space environments

Advantages over conventional solutions

DBB monoflange valves replace classic assemblies of ball, needle, and bleed valves, offering significant advantages:

Ultra-compact design: ideal for instrumentation racks or top-mounted lines

Weight and space savings: crucial in offshore platforms or compact structures

Faster installation and maintenance: fewer components means quicker work in the field

Increased reliability: fewer flanged or threaded joints reduce failure points from vibration, corrosion or fatigue

Standards-compliant: designed to meet API 6A / 6D, ASME B16.34, NACE MR0175, with optional PED, ATEX or SIL certifications

Real-world applications

DBB monoflange valves are widely used in:

- Differential pressure taps on separators, exchangers or filters

- Purge or vent lines in pumping and compression systems

- Packaged equipment (skids) where compactness and serviceability are essential

- High-pressure/high-temperature processes, like chemical injection or steam lines

- SIL-rated systems or units with safe shutdown requirements

In one of our recent projects for a gas treatment plant, we integrated DBB monoflange valves made from superduplex, with NPT threads and 1/4” gauge ports, rated for 414 bar and 200 °C. This setup reduced the required installation space by 35% compared to modular configurations—without compromising safety.

Materials, configurations and options

At Sistemiza, we supply DBB monoflange valves in a wide range of materials and designs:

- Materials: stainless steel 316/316L, duplex, superduplex, Monel®, Inconel®, Hastelloy®, etc.

- Connections: threaded (NPT, BSP), flanged (ASME, DIN), or weld ends

- Shut-off types: needle or ball valves, depending on the application

- Bleed ports: side or bottom outlet, with valve or plug

- Custom designs: options include multi-connection blocks, check valves, or pneumatic actuators

What about the cost? Is it worth it?

Although the unit cost of a DBB monoflange valve may be higher than a standard valve, the total cost of ownership (TCO) is significantly lower:

- Faster installation = fewer man-hours

- Fewer joints = less maintenance

- Higher reliability = fewer failures or shutdowns

- Space savings = lighter, more compact assemblies

Integration with filtration and instrumentation

At Sistemiza, we go beyond supplying components—we design fully integrated solutions combining filtration, valves and instrumentation into ready-to-use Plug & Flow systems.

A DBB monoflange valve is not just an accessory. It can serve as the interface between a coalescing filter, a pressure manifold, and a critical process line. When correctly integrated, it enhances overall system performance, safety and control.

Need a custom solution?

Our engineering team advises on every project—from material selection to system layout. Whether you’re working with aggressive gases, corrosive fluids or extreme conditions, we’ll help you select the right DBB monoflange valve.

Want to improve your process?

📩 Contact us at info@sistemiza.com or visit www.sistemiza.com

🔧 Experts in fluid handling system integration